Functional Nanomaterials & Energy Devices Lab

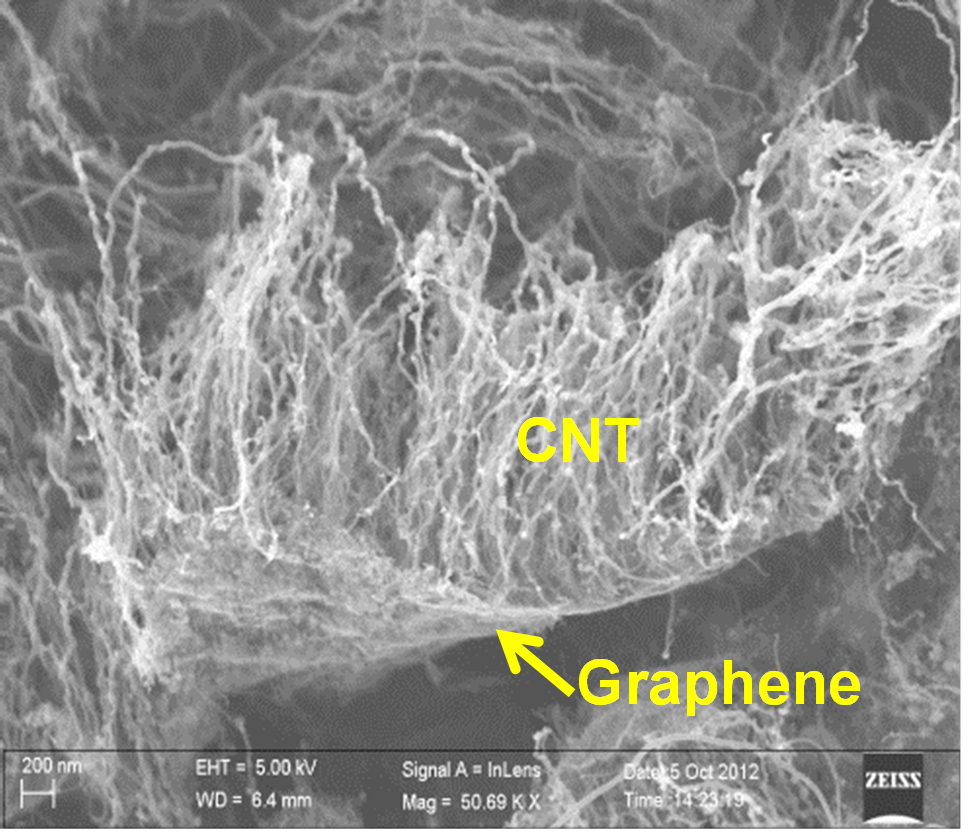

Our group is involved in exploring structural and functional concepts of nanomaterials and their composites for energy, health and environmental applications. We synthesize a variety of nanoscale structures such as carbon nanotubes; graphene; silicon nanorods; polymer, metal and metal oxide nanoparticles using chemical vapor deposition, sol-gel, hydrothermal and polymerization techniques. The connection between energy, sustainability, health and nanotechnology is an area that shows potential for great scientific and technological advances.

Energy Related Applications

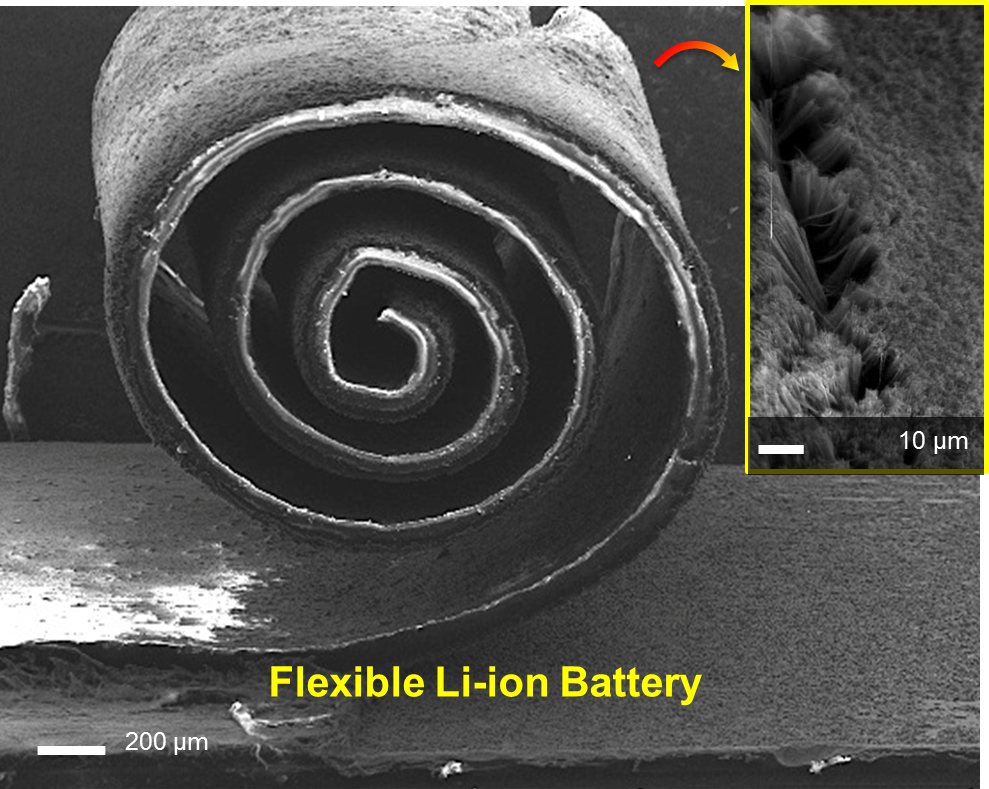

The performance of rechargeable energy devices such as lithium-ion, lithium-sulfur, lithium-air batteries and supercapacitors is inherently tied to the properties of materials used to build them. Our research focuses on the enhancement of these properties for next generation energy devices through nanoscale engineering and novel designs. We are looking at several nanostructured materials such as Si nanowires, graphene, carbon nanotubes and their hybrid combination with metal oxides and polymers as electrodes and several polymer and room-temperature ionic liquid (RTIL) based composite electrolytes for full military range temperature operation. Specific interests include

- Development of high capacity anode and cathode materials for lithium ion batteries

- Thermally stable electrolytes for Li-ion batteries and supercapacitors

- Design aspects of three dimensional microbatteries

- Lithium-sulfur and Lithium-air chemistries using novel electrolytes

Integrated Energy Devices

Though energy harvesting and storage are independent mechanisms, each has their own significance in the energy cycle. Energy is generally harvested from mechanical motions, temperature variations, and other phenomena which are inherently sporadic in nature, the harvested energy stands a better chance at efficient utilization if it can be stored and used later depending on demand. In essence this means a device that can harness power from surrounding environment and provide a steady and reliable source of energy. Further, flexible energy sources are the need of the hour, as the longevity of stiff devices will suffer due to the repeated fatigue cycles they experience both directly as well as due to thermal expansions under harsh conditions. We currently focus on

- Biomechanical energy harvesting from human movement

- Developing ultrathin wearable energy devices

- Powering autonomous sensors

- Lightweight nanocomposite materials

Smart Coatings

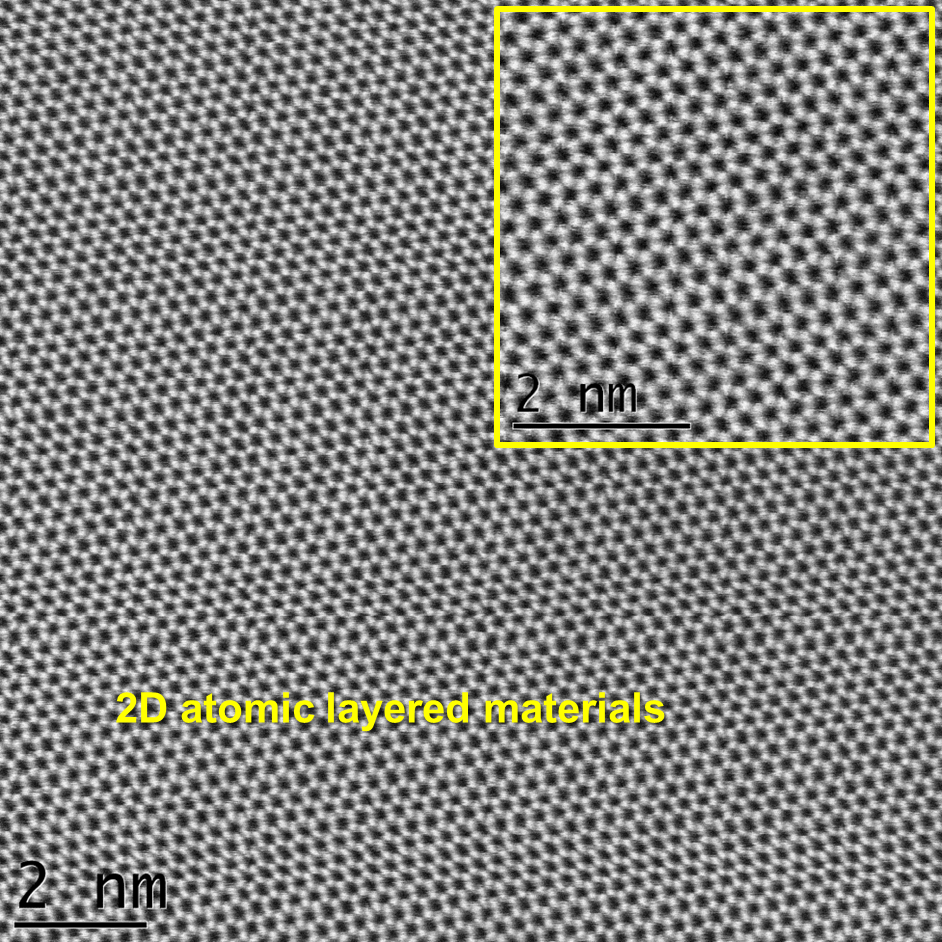

With the advent of various kinds of nanostructured materials, it is possible to envision coatings with highly tailored properties on a large variety of substrates. Tunable functional properties of nanomaterials (such as graphene, hexagonal boron nitride – h-BN, MoS2, carbon nanotubes etc.) are very ideal to be efficient filler for high quality polymer matrix nanocomposite coating. Our research interest lies on developing nanomaterials based coatings that can have properties ranging from superhydrophobicity, amphi-phobicity (high wetting angles for both water and organic solvents), porosity, wetting transparency, ranges of mechanical properties, electrical and thermal conductivity and other chemical and optical functionalities. We develop Corrosion-resistant, Thermal-resistant, Scratch-resistant, Fire-resistant, Abrasion-resistant, Wear and friction resistant and Electrically-conductive coatings for wide range of industrial applications.

Nanostructured Low Dimensional Materials

Our lab deals with synthesis and characterization of a variety of low dimensional materials. Mechanical, thermal, electrical, optical, chemical, and sensing properties of materials are tuned by introducing nanoscale size affects thereby exploit them for targeted applications. We currently focus on the following materials/techniques

- CVD synthesis of carbon based 1D, 2D and 3D nanostructures

- Chemical reduction and thermal exfoliation techniques for 2D materials

- Hydrothermal and sol-gel techniques

- Electropolymerization

Facilities

- CVD Facility for the growth of graphene, carbon nanotubes, metal oxide nanostructures

- Electrodeposition facility for growing metal/metal oxide/polymer nanowires/nanotubes.

- Annealing furnace, Vacuum and Dry Ovens

- High pressure reactors for nanomaterials synthesis

- Multichannel Electrochemical workstation

- Glove Box

- Battery assembling and Testing units

- In house fabricated sensor work station